High-reach demolition is one of the most dangerous parts of any jobsite. Overhead materials can shift without warning, and manual tools often put crews directly in harm’s way. A demo pole demolition tool allows operators to remove ceilings, walls, and elevated structures while staying grounded and in control. Instead of relying on ladders, lifts, or risky hand work, contractors gain reach, control, and distance.

This article breaks down why using a demo pole demolition tool isn’t just about speed—it’s about smarter, safer demolition when working above shoulder height.

The Problem with Traditional High-Reach Demolition

Traditional high-reach demolition often depends on manual force and risky positioning. Crews climb ladders, stretch tools overhead, or work from unstable platforms. That approach increases fatigue and reaction time while reducing control.

Common challenges include:

- Limited reach and leverage

- Poor visibility above eye level

- Increased fall and debris risks

- Slower removal due to repositioning

Even when powered equipment is used, not all tools qualify as a true high-reach demolition tool. Without proper attachment design, operators still fight gravity and unstable materials. This is why relying on manual methods instead of a demo pole demolition tool often leads to delays and safety concerns.

What a Demo Pole Attachment Is Designed To Do

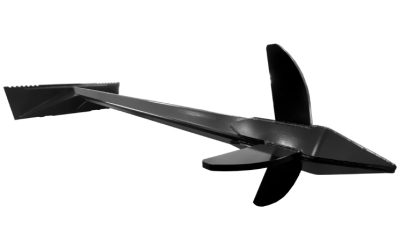

A demo pole is built for one purpose: controlled demolition

Unlike improvised tools, a demo pole demolition tool allows operators to:

- Push, pull, and pry overhead materials

- Push thru block walls

- Maintain distance from falling debris

- Control removal direction

Mounted as a skid steer demo pole the attachment turns a machine into controlled demolition equipment. Instead of forcing material down unpredictably, the operator dictates how and where it comes loose.

This control is what separates professional demolition from risky improvisation.

Advantages in Ceiling, Wall, and Overhead Removal

Overhead demolition demands more than brute force. Ceilings and elevated walls fail in stages, not all at once. A demo pole demolition tool lets operators work methodically instead of reacting to sudden collapse.

Key advantages include:

- Steady pressure instead of impact force

- Clean separation of materials

- Reduced secondary damage

As one of the most effective wall removal tools, the demo pole shines in interior environments. It improves interior demolition safety by keeping operators clear of falling debris. For jobs requiring high-access demolition, the extended reach eliminates constant repositioning and improves workflow consistency.

Safety Benefits for Operators and Crews

Safety improves when distance increases, and control remains constant. A demo pole demolition tool supports overhead demolition safety by removing workers from direct exposure zones.

Major safety benefits include:

- Less overhead strain

- Reduced fall hazards

- Improved line of sight

- Predictable material movement

Using safe demolition practices means choosing tools that reduce reaction-based work. Whether mounted as a skid steer demo pole or an excavator demo pole, the attachment allows demolition to happen on the operator’s terms—not the structure’s.

That reliability lowers fatigue and keeps crews focused throughout long shifts.

Ideal Job Types for Demo Pole Usage

Not every demolition task requires extended reach, but many benefit from it. A demo pole demolition tool proves especially valuable in environments where height and control intersect.

Ideal job types include:

- Interior commercial strip-outs

- Warehouse ceiling removal

- Wall separation in occupied buildings

- Structural prep for renovations

In these scenarios, controlled demolition equipment minimizes disruption while maintaining productivity. Contractors working with overhead systems often pair a demo pole with tools like The Beak to manage debris after removal, creating a smooth transition from teardown to cleanup.

Conclusion: A Critical Tool for Modern Demolition Work

Modern demolition demands efficiency without sacrificing safety. A demo pole demolition tool delivers both by turning risky overhead tasks into controlled, machine-assisted operations. By improving reach, control, and crew safety, it supports smarter workflows and safer jobsites.

If you’re ready to upgrade your approach to high-reach removal, contact us to learn how the right demo pole demolition tool can fit your machine and your next project.