Ask any contractor which part of demolition slows them down, and you’ll get the same answer every time: overhead debris, crumbling ceilings, and walls that never fall the way you expect. That’s exactly where a demo pole attachment earns its reputation. The moment it’s on the machine, the entire job feels different—safer, smoother, and far less chaotic. Crews get the distance they need, the control they want, and the confidence that comes from keeping danger out of arm’s reach. Whether you’re peeling off drywall, breaking stubborn framing, or pushing down concrete panels that refuse to budge, a demo pole attachment takes the pressure off the operator and lets the machine do the hard work. It delivers cleaner angles, better leverage, and a safer approach to tight interior spaces. It’s no surprise that this tool has become a must-have demo pole attachment for demolition teams who want to work smarter, not riskier.

What Is a Demo Pole Attachment?

A demo pole attachment is a heavy-duty extension tool designed to give operators reach and strength when knocking down walls, ceilings, and overhead materials. Paired with a skid steer or excavator, it acts as a powerful arm that removes danger by keeping the operator away from unstable surfaces.

Before diving into techniques or applications, here’s what makes it stand out:

- Works as a skid steer demo pole or demo pole for excavators

- Designed for controlled, safe removal of tough materials

- Strong enough to push, pry, and break without putting workers in harm’s way

- Perfect for tasks where ladders, sledgehammers, and risky hand tools offer little protection

This single demolition pole tool gives crews the ability to tear down more while taking fewer risks. Its versatility and rugged build make it one of the most effective high-reach demolition tool options available.

10-Foot Working Reach: Why It Matters

A 10-foot reach doesn’t sound dramatic until you’re trying to remove ceiling joists, HVAC ductwork, or wall panels that refuse to budge. Standing beneath them is never the ideal plan.

With a demo pole attachment, that 10-foot range means:

- More distance from falling debris

- Strong leverage when breaking apart tight structures

- Better reach for high spots without lifts or ladders

- Faster breakdown of large panels and overhead materials

This feature also reduces fatigue since the machine handles the force. For operators using interior demolition equipment, a reach like this leads to quicker jobs and fewer safety concerns. On many sites, it’s the upgrade that changes how teams approach overhead work.

Applications: Walls, Ceilings, Interior Strip-Outs & More

Before diving into specific tasks, it helps to know how wide the tool’s range is. The demo pole attachment handles more than most crews expect.

Use Cases Contractors Rely On

- Wall demolition using a stable wall demolition attachment rather than risky hand swings

- Ceiling and overhead debris removal, where overhead demolition safety matters most

- Interior strip-outs, ideal for remodels and commercial gut jobs

- Concrete panel breakdowns with compatible concrete wall removal tools

- Tight-area demolition, especially in buildings with low clearance

- Selective demolition, keeping neighboring structures intact

The precision of this demolition pole tool also helps reduce unwanted damage during controlled tear-downs. It becomes a core part of any contractor’s list of controlled demolition tools, especially when time and safety are top priorities.

This attachment doesn’t just hit things—it helps operators work smarter, faster, and cleaner.

Safety Benefits Compared to Traditional Methods

Anyone who has spent time on demolition sites knows that handheld tools, ladders, and overhead swings bring risks that never feel worth it. A skid steer demo pole removes much of that danger by giving operators distance and stability.

Key Safety Advantages

- Machines absorb impact, so workers don’t

- Lower risk of falling material hitting the operator

- No ladders needed for overhead tear-outs

- Better control of fragile surfaces and unstable walls

- Clear path for falling debris instead of unpredictable collapse

Using the tool with other skid steer demolition accessories also makes the whole workflow safer. The control and visibility improve, and operators stay shielded from materials that would normally need hands-on removal. These are gains that pay off every single day on the job.

Pairing the Demo Pole with Other OMNI Attachments

Before getting into specific combinations, it helps to understand why pairing matters in the first place. Demolition is never a one-tool job. Each phase—from breaking material loose to hauling it away—benefits from equipment that works together instead of working alone. When the setup is stronger, the results show up in cleaner floors, faster progress, and fewer stop-and-start moments on site.

Contractors often pair the demo pole attachment with:

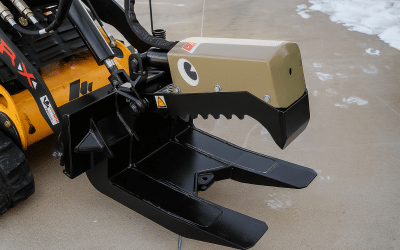

1. The Beak

After the demo pole attachment brings materials down, the Beak jumps in as the grab-and-go workhorse. It grips debris, broken panels, framing, and concrete chunks with ease, making cleanup far quicker than manual handling.

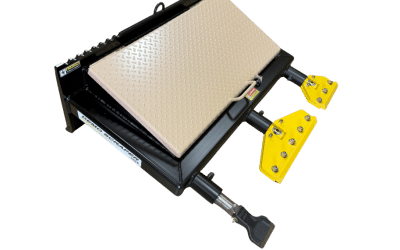

2. Roto Fork RF-50

Perfect for interior tear-outs that require repositioning, rotating, or controlling bulky pieces. This add-on gives operators smoother handling and better angles when moving materials after the initial break.

3. Additional Cleanup and Prep Tools

Once the high-reach demolition tool has finished knocking everything loose, smaller accessories step in to push, gather, and prep the area for hauling or the next phase of work.

Using these tools together cuts cleanup time, streamlines the workflow, and lets operators move effortlessly from breaking to grabbing to hauling. It feels like a full demolition system, not just a single tool upgrade.

Why Contractors Choose Demo Poles

Contractors choose the demo pole attachment because it saves time, boosts confidence, and helps them take on tough wall and ceiling projects without the usual stress. With the reach they need and the control they want, it becomes the go-to tool for safer removal, smoother strip-outs, and more efficient workflows. Whether you’re using a demo pole for excavators or a skid steer demo pole, the result is the same: better work with fewer risks. For a reliable upgrade to your demolition process, contact us today and learn how a demo pole attachment can elevate your next project.