Every busy crew knows the best days on a jobsite are the ones where material moves fast, operators stay in control, and nothing slows the workflow. That’s exactly why a rotating pallet fork attachment has become such a game-changing upgrade. Instead of fighting awkward angles, juggling tight spaces, or repositioning machines over and over, the operator gets smooth rotation, stronger lifting, and precise handling from one simple tool. A rotating pallet fork attachment turns long tasks into short ones and gives crews more flexibility during demolition, landscaping, and material staging. Whether you’re loading awkward debris, rotating pallets into narrow corners, or working with heavy products all day, a rotating pallet fork attachment helps everything move faster with far less stress. And thanks to its smart design and powerful rotation, a rotating pallet fork attachment feels like a must-have for modern efficiency.

What Makes a Rotating Pallet Fork Different?

Before diving into performance benefits, it helps to understand what sets a rotating pallet fork attachment apart. Standard forks lift and move material—but only forward. A rotating setup changes the entire game.

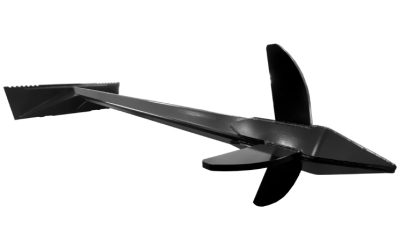

A Roto Fork RF-50 system gives you rotational control that keeps loads stable and machines in place. You don’t need to shuffle back and forth to adjust angles. Instead, rotating skid steer pallet forks twist smoothly with a 360-degree pallet fork rotation that adapts to awkward spaces.

The internal hydraulic worm drive slewing ring provides controlled power. This lets teams use the tool for heavy-duty pallet handling, awkward lifts, and even demolition material handling where debris doesn’t sit neatly on forks.

Crews choose it because it works as a reliable skid steer pallet fork attachment and performs well in tight zones where precision matters.

Key Features of the Roto Fork RF-50

The Roto Fork RF-50 is more than a basic fork—you get features designed to handle tough environments and constant use.

1. True 360° Rotation

This is the standout feature. With full movement from 360-degree pallet forks, operators line up heavy materials without repositioning the machine.

2. 5,000 lb Capacity

Built for heavy-duty pallet handling, the RF-50 handles heavy loads without strain. This includes landscaping bundles, demolition debris, and construction supplies.

3. Slewing Ring Technology

Its hydraulic worm drive slewing ring delivers smooth, controlled rotation even under load. No jerky motion. No unstable shifting.

4. Compatible With Most Skid Steers

Works as a high-performance skid steer pallet fork attachment and integrates well with a wide range of machines.

5. Designed for Demolition and Material Handling

Contractors rely on it as part of their skid steer demolition tools, especially when managing mixed debris or lifting awkward sections of material.

6. Reinforced Steel Fork Frame

Built with a heavy-duty steel frame that resists bending and fatigue during repeated high-load use on demanding jobsites.

7. Precision Operator Control

Smooth, responsive rotation allows accurate load positioning in tight spaces, reducing rework and improving control.

When crews search for a good, reliable rotating fork system, many rely on the Roto Fork RF-50 from Omni Attachments

Applications in Demolition, Landscaping, and Material Handling

A rotating pallet fork attachment shines in multiple industries because rotation removes friction from everyday tasks.

Demolition

- Ideal pallet forks for demolition when removing structural debris

- Helps operators lift, rotate, and place awkward material

- Works alongside demolition material handling equipment

Landscaping

- Rotates pallets of sod, mulch, rock, or hardscape blocks

- Cuts loading time with rotating skid steer pallet forks

- Adds precision in tight landscape zones

General Material Handling

- Perfect for warehouse-style movement on jobsites

- Eliminates the need for constant repositioning

- Complements jobsite efficiency tools with seamless workflow

In every category, the RF-50 pairs with material handling carts and other equipment for streamlined work.

Efficiency Gains Compared to Standard Pallet Forks

A rotating pallet fork attachment increases efficiency in ways standard forks simply can’t match.

Key Time-Saving Advantages

- Less machine repositioning thanks to full rotation

- Better control in narrow work zones

- Faster loading and unloading

- Smoother handling of irregular materials

When paired with jobsite efficiency tools, the RF-50 turns slow material handling into a steady, predictable routine. Its rotational motion prevents wasted time and makes heavy-duty pallet handling easier.

Teams often combine the RF-50 with demolition carts for an even smoother workflow.

Safety Advantages for Operators and Crews

Safety matters as much as speed, and a rotating pallet fork attachment offers significant improvements.

Safer Handling, Less Risk

- Rotation reduces awkward lifting angles

- The hydraulic worm drive slewing ring keeps loads stable during turns

- Crews avoid unsafe repositioning in tight areas

- Operators move debris and materials more cleanly with pallet forks for demolition

Since materials stay balanced and machines stay still, it becomes a valuable part of skid steer demolition tools across active jobsites.

The result? Fewer risks and more control during both demolition material handling and general movement.

Why Contractors Choose the RF-50

Contractors choose the rotating pallet fork attachment because it turns slow, repetitive tasks into efficient, safe, and smooth operations. The Roto Fork RF-50 brings 360° rotation, strength, and control to daily work. Whether you’re using rotating skid steer pallet forks, lifting loads with 360-degree pallet forks, or handling material as a skid steer pallet fork attachment, this tool makes each job site run better. For a reliable upgrade in material movement and pallet forks for demolition, contact us today and see how a rotating pallet fork attachment improves your workflow from day one.