Below, we break down how traditional grapples and The Beak grapple perform in real-world conditions—focusing on grip, control, and durability when the material gets heavy, messy, and unpredictable.

What Makes a High-Performance Grapple?

A grapple earns its place on a jobsite when it does more than grab and drop. Heavy material demands control, strength, and consistency. Before comparing models, it helps to understand what separates an average attachment from a serious tool.

A high-performance grapple should deliver:

- Strong, balanced clamping force

- Clean visibility for the operator

- Control over irregular loads

- Minimal material slip during transport

- Confidence during long workdays

Many contractors debate grapple vs bucket setups when dealing with debris. Buckets carry volume, but grapples control shape. That difference becomes critical when handling unpredictable loads. A heavy-duty grapple attachment focuses on gripping power rather than containment, giving operators more control and fewer dropped loads.

This baseline sets the stage for a comparison that focuses on how the equipment actually performs on the job, not just what the spec sheet says.

The Beak’s Key Features Compared to Standard Grapples

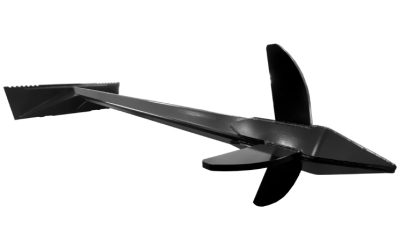

Traditional grapples rely on parallel jaws or wide tine spacing. They work, but they struggle with uneven debris. The Beak grapple uses a focused, aggressive clamping design that bites into material rather than squeezing from both sides.

Key design differences include:

- A pointed gripping profile for precise contact

- Reinforced steel construction for extreme loads

- A compact frame that keeps the weight close to the machine

- Better control when lifting awkward debris

Standard grapples often spread force across wide jaws. That approach weakens grip on narrow or broken material. The Beak grapple concentrates force where it matters. This makes a real difference in a debris grapple skid steer setup, especially during demolition or cleanup.

For operators weighing grapple vs bucket options, this focused grip explains why grapples outperform buckets when material shape matters more than volume.

Performance in Concrete, Slab, Log, and Debris Applications

Heavy debris reveals attachment weaknesses fast. In concrete work, broken slabs don’t sit evenly. Traditional grapples tend to pinch, shift, and drop loads mid-lift. The Beak grapple clamps inward and downward, keeping debris locked in place.

For concrete debris handling, this control reduces re-grabbing and machine repositioning. Crews spend less time adjusting and more time moving material.

In forestry and land clearing, logs roll and twist. Standard jaws struggle to keep round material stable. The Beak grapple works naturally alongside forestry grapple tools, gripping logs securely without rolling or shifting.

During slab work, a pointed design acts like a slab removal attachment, allowing operators to lift and stage concrete cleanly. After storms, tangled debris piles demand precision. As part of storm cleanup equipment, this design grips mixed materials without constant readjustment.

These real-world scenarios highlight why a proper skid steer grapple comparison must focus on performance under stress.

Durability and Operator Efficiency Differences

Durability isn’t just about steel thickness. It’s about how force travels through the attachment. Traditional grapples spread stress across multiple pivot points. Over time, that leads to uneven wear and looseness.

The Beak grapple channels force through a reinforced central structure. This reduces flex and improves long-term reliability. As a heavy-duty grapple attachment, it holds shape under repeated heavy loads.

Operator efficiency improves when the tool works predictably:

- Fewer dropped loads

- Less repositioning

- Better sightlines

- Faster cycle times

A well-designed debris grapple skid steer setup also improves safety. Controlled material means fewer surprises during lifts. Over long shifts, that reliability makes The Beak grapple feel like an extension of the machine rather than a limitation.

These differences separate average tools from the best skid steer grapple options on the market.

When to Choose The Beak Over a Traditional Grapple

Not every attachment fits every job. Traditional grapples work well for lighter, more uniform material. But when debris becomes heavy, uneven, or unpredictable, the Beak shows clear advantages. Below is a practical comparison to help contractors decide what fits their workload best.

Traditional Grapple

Better suited for light brush, limbs, and uniform debris

- Works well when material stacks neatly and stays balanced

- Offers basic gripping but limited control on irregular loads

- Can struggle with shifting concrete or uneven weight distribution

The Beak Grapple

- Excels at handling broken concrete, slabs, and irregular debris

- Strong bite delivers reliable material gripping solutions for unpredictable loads

- Maintains control in tight demolition zones and confined work areas

- Ideal for storm cleanup piles with mixed shapes and weights

- Built as a heavy-duty grapple attachment for demanding, high-impact work

For contractors weighing a grapple vs bucket decision, the difference comes down to control. Buckets move volume, but grapples manage chaos. When debris varies in size, shape, and weight,The Beak consistently ranks among the best skid steer grapple options for grip stability, durability, and operator confidence.

Why Contractors Rely on The Beak System

Contractors don’t have time for tools that slow them down. They need attachments that work on the first grab and hold through the entire lift. This is why many professionals rely on The Beak lineup for demanding work.

Depending on machine size and job type, operators can explore:

- The Beak for full-size skid steers

- Mini Beak for compact machines and tight access

- Log Spoon for specialized log handling and staging

Each option builds on the same gripping concept while adapting to different machines and tasks. This flexibility strengthens any skid steer grapple comparison that looks beyond one-size-fits-all solutions.

Why This Skid Steer Grapple Comparison Matters

Equipment choices affect productivity, safety, and long-term costs. A smart skid steer grapple comparison looks past price and focuses on performance where it counts. The Beak grapple stands out by solving real problems contractors face every day.

Traditional grapples clamp. The Beak grips. That difference shows up in fewer dropped loads, faster cycles, and better control. In demanding environments, those gains compound quickly.

If you want more control, durability, and jobsite confidence, contact us to find the right Beak attachment for your machine.